We Are Open and Have Returned to Normal Operations

Previous slide

Next slide

The Helm MKII is our first major update of the Helm fork lineup and improves on its predecessor in nearly every way. Hand-built in Western North Carolina and rigorously tested and developed in the Appalachian Mountains.

Featuring an updated damper design with new compression and mid valve circuits, a new SKF oil seal head, and Motorex 2.5 weight damper oil. All of these elements work to reduce friction and increase sensitivity.

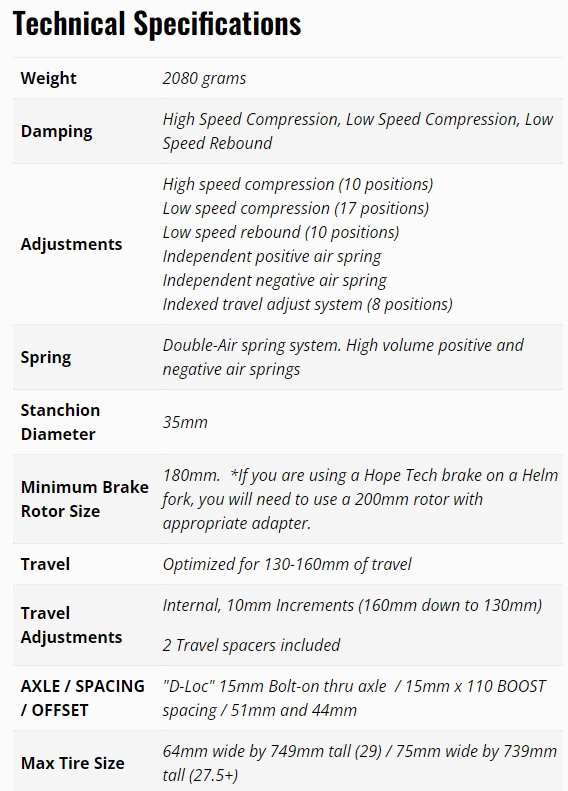

Tuning your suspension starts with dialing in your spring. The independent positive and negative air chambers – along with the self contained indexed volume adjustment system allow all Helm air forks to be set up for any rider and any style.

The Helm MKII air spring has a redesigned air piston which increases air volumes and reduces friction, greatly improving traction and suppleness on trail. The threadless seal head and manual negative air charge button designs allow for easy travel setting adjustments and the ability to properly set up riders of all different sizes and abilities.

– Zach Peterson, Vital MTB

Every single Helm fork is designed, built, inspected, tested and packed by a dedicated team of suspension professionals at our facility in Fletcher, North Carolina. Our suspension team’s attention to detail is illustrated in our three step Dyno testing, ensuring that our hand built products reach high standards of precision and performance.

This process includes:

The HELM’s Damper is the control center of the fork – highly sensitive check springs, valves and shims control the flow of oil with every compression and rebound as you ride down the trail. Cane Creek’s Development Team equips the MKII with new compression and mid valve circuits to maintain control during heavy braking and square edge scenarios.

A redesigned SKF Oil Seal Head and Motorex damper oil work together to protect the internal damper components while simultaneously reducing friction.

In keeping with our love for building components that stand out from the crowd, the Chroma Studio is here to add some additional style to your bike.

Make it unique with these timeless colors.

Nice fork, but don’t care for neg chamber filling process. Not sure if or how much air is transferring to the neg side when pressing the valve. Would rather have another shreader valve to fill the chamber.

Verified review - view original

Verified review - view original

My main off tarmac riding is done on open grazing land. During the winter it gets very chewed up from the cows. It makes for next to impossible riding at times and even after they grade the roads in the spring they can still be quite rough. I had a suspension stem which helped somewhat but the front end had a hard time connecting to the ground. After only a few ride with the Invert I've found that the frontend now stays connected to the ground and I'm able to ride faster and smoother.

My local bike shop owner hadn't heard of the Invert when I brought it in for him to install. After a quick ride around town he was impressed by how responsive and positive the steering was.

Verified review - view original

Verified review - view original

Monday: 10:00 am – 5:00 pm

Tuesday – Thursday: 10:00 am – 5:00 pm

Friday: 10:00 am – 5:00 pm

Saturday – Sunday: Closed