We will be out of office 12/23 - 1/1. Happy Holidays!

Limited Edition: eeBrakes Magnum

Previous slide

Next slide

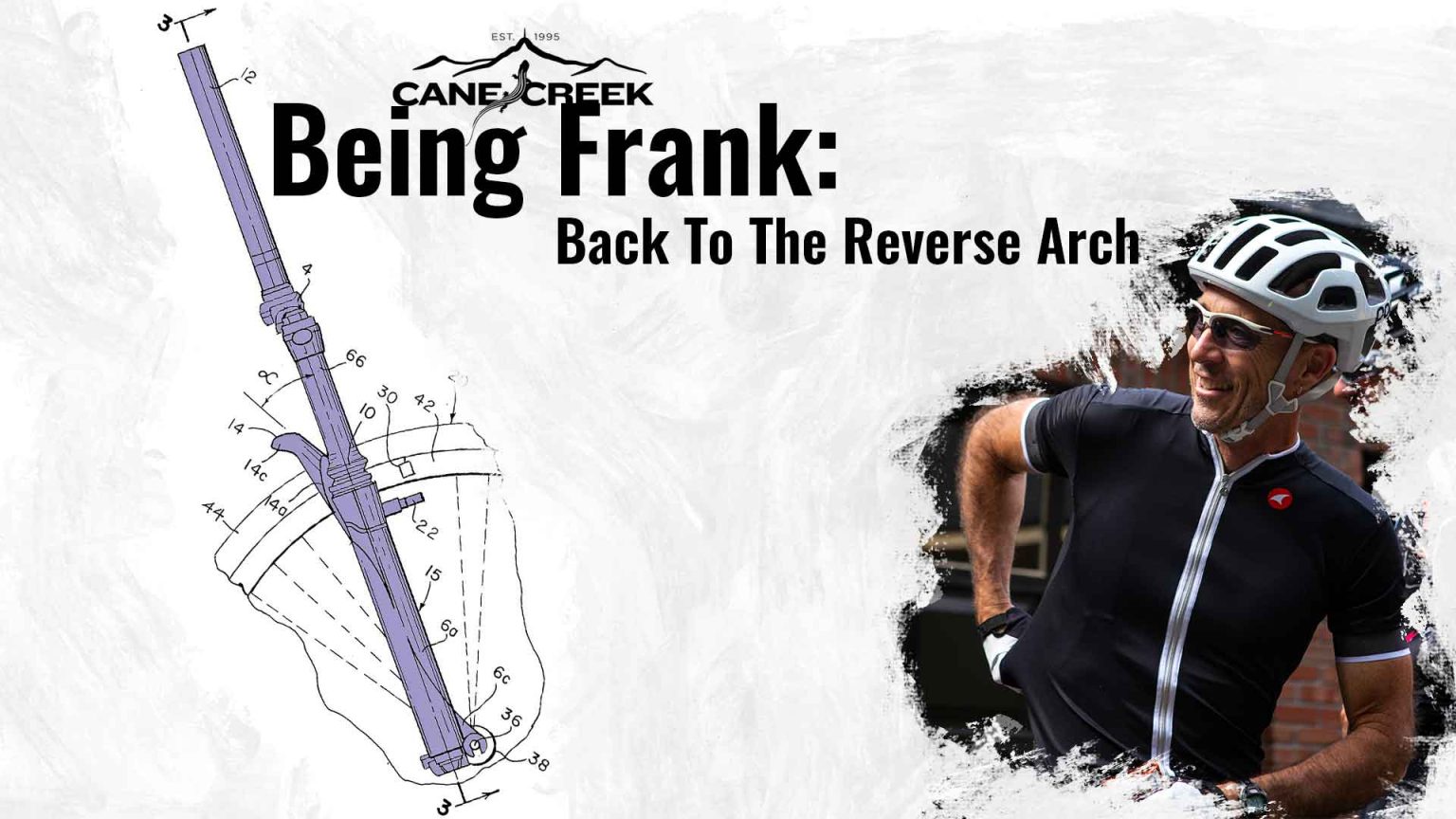

August 2023

While visiting the bike shop section of an REI store in the San Fernando Valley back in 2000, I found myself dumbfounded while staring at the line of mountain bikes on display. The bikes I was looking at all featured black suspension forks from various makers, and they all looked alike.

I began wondering why they all had the same design – like why the arch was the way it was? On my drive back to work at Answer Products (aka Manitou) I mentally walked through the evolution of suspension design searching for an answer.

The early mountain bike suspension forks were multi piece designs that needed to be connected and aligned. The two legs were bolted together via an arch, and that arch was a handy location for the cantilever brake bosses. Since the brakes were on the front, the arch needed to be on the front. A few years later one-piece lowers were introduced, but the arch remained on the front along with the brake bosses. In the late 1990’s when disc brakes started becoming relevant on mountain bikes, the last reason for the front-mounted arch disappeared, yet arches remained on the front. I asked myself if arches could/should be on the back side of the fork.

Also during the late nineties and early two-thousands, suspension fork development was in high gear, and one of the areas needing improvement was fork chassis stiffness. The lack of torsional and fore-aft stiffness was a performance limitation, and we were all chasing improvement. Consequently, arches got bigger, and the “wrap” of the arch around the inside and outside of the lower legs became pronounced. During this process we discovered that adding material to the inside wrap dramatically improved stiffness compared to adding to the outside. But adding inside wrap was limited because the cantilever (now V-Brake style) needed to open for wheel removal.

When I returned to work after the REI visit, I stopped in Joel Smith’s office. Joel led our marketing team, was a very skilled rider, and had a heady childhood growing up a son of motorcycle legend Malcolm Smith (see the movie On Any Sunday). I told Joel about this crazy idea of putting the arch on the back, and after walking him through my thought process, we talked about the possibility of the arch contacting the frame’s down tube during fork compression.

Some of the people that have most impressed me during my thirty-two years in the bicycle industry are the ones that make things with their hands, seemingly out of thin air – the fabricators. And Manitou had a great fabricator with a fully equipped shop. So I talked to him about mocking up a “looking sample” for us to gauge appearance and frame clearance. Yes, we had multiple CAD jockeys, but there is no substitute for seeing real things in person. In a day or two our fabricator walked in with the mock up that looked surprisingly refined. When I asked how he made it, he said he cut off the arch, welded on the back, and then smoothed everything with some body filler. When my boss heard someone welded magnesium in our building, he nearly blew a gasket. But fortunately our building didn’t blow up!

Once we saw how unique the look was and that frame clearance was not an issue, I sat with one of our design engineers, Jim Rathbun, to see a from-the-ground-up casting take shape with an arch on the back. We learned along the way that the arch could be shorter, stiffer, and possibly lighter on the back because the tire was “falling away”. We also found we could add more inside wrap, as mentioned above, to add stiffness and not limit V-Brake opening. Which led to a to a big debate once the new design was completed, validated, and patented.

Image credit: Mountain Bike Action circa 2002

As mentioned, disc brakes were coming on the scene at the time, but a lot of bikes still had V-Brakes. I pushed for only offering this new fork design for disc brake bikes for three reasons: 1.) the fork with arch on the back looked much better without V-Brakes on the front, 2.) I believed disc brakes were the future, and 3.) I wanted the fork to make a bold statement for Manitou with regards to a unique design for the disc brake future. But the commercial realities were impossible to ignore – those being the thousands of bikes still using V-Brakes that our fork would not work on – and I lost. Relatedly, my idea to have different arch designs for different cycling disciplines (e.g. arch in the back for DH, arch in the center for XC, and arch on the front for trail) also got snuffed out.

We came up with the name Reverse Arch along with an RA logo and launched the design on the Manitou Black fork in 2001. While Manitou ownership changed several times after the Black, the most recent owner, Hayes, has continued using the Reverse Arch for 20+ years on Manitou forks. Why tell this story now? Well, recently the Reverse Arch patent expired, and Fox promptly introduced its new gravel fork with a Reverse Arch. And this week photos surfaced of a new Fox mountain bike fork with what appears to be a Reverse Arch. Some ask me how I feel about others, in this case Cane Creek competitors, using the Reverse Arch. I say that I think it is great because even after twenty years the Reverse Arch idea is continuing to prove itself.

Monday: 10:00 am – 5:00 pm

Tuesday – Thursday: 10:00 am – 5:00 pm

Friday: 10:00 am – 5:00 pm

Saturday – Sunday: Closed