Let me be… um, frank. Some forum commenters are losers. Unwilling to use their real names, these commenters pontificate without accountability, common sense, tact, and in many cases knowledge. There have always been these types in the crowd, and I expect there will always be. But in the age when the heckler sounded off during the gathering of a village of a hundred, the person could be seen, challenged, evaluated, and disregarded if they spewed garbage. Now with amazingly powerful and portable digital devices, one can say anything, anywhere, anytime, in seconds, and invisibly without consequence.

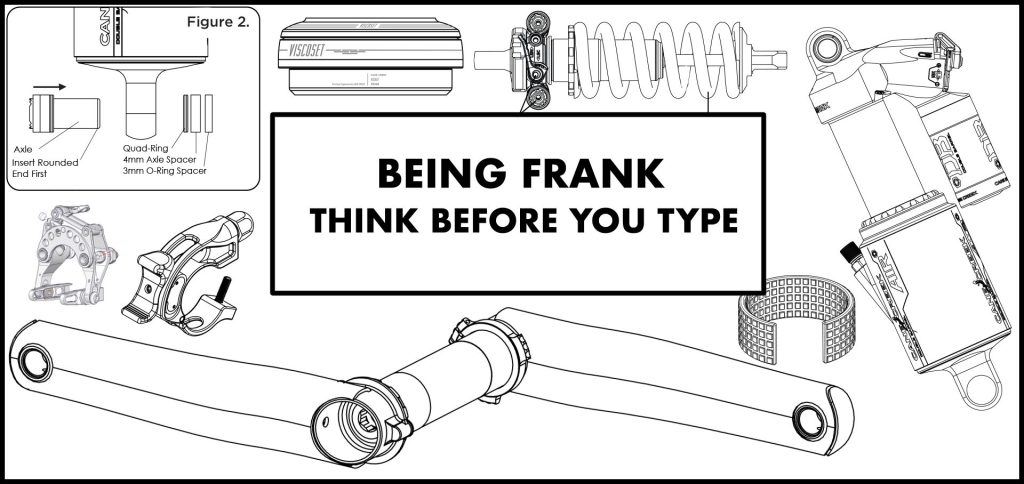

The recent introduction of the Cane Creek eeWings titanium crank received tremendous response, and we were certainly interested in what was being said. It turned out to be the biggest and best response the company has seen in years. While the hecklers were out there, they were outnumbered significantly. But the sheer stupidity of some of their statements stood out, while others were clearly misinformed or making reckless assumptions.

There were comments like titanium is soft, turns green over time, and is one of the most flexible metals. All of which are incorrect. Then there were the experts that said titanium cranks must be more flexible than carbon cranks and that spindle joint is not as durable as a splined or lobed interface. Well we’ve been testing cranks for months to ISO bicycle industry standards (required in Europe), and eeWings consistently flex significantly less than carbon cranks under a specific load and absorb more force before permanent deflection. This result is due to a combination of titanium’s superior stiffness compared to aluminum (remember, those carbon cranks are connected by an aluminum spindle), the lack of deflection in the titanium Hirth joint compared to an aluminum lobed joint, carbon fiber is great under tension but unidirectional fibers must be laid up carefully to handle bending and twisting loads that are translated to a shearing load at the spindle compared to titanium’s equal strength in all directions, and the fact that regardless of material, a tube’s stiffness is greatly impacted by the size and shape of its cross section. Early titanium frames were flexible because they were built from small diameter tubes whereas aluminum frames were much larger in diameter.

There were also the inexplicable comments such as the spindle parts do not look machined, the opportunity cost to the company was not worth it (how in the world would someone know what it cost us to develop eeWings and what we had to pass on to do so?), the SRAM ring interface is obsolete (the brand that made 1x reality for the masses and produces more 1x cranks/rings than anyone in the world), and the Chinese cannot weld titanium. The last is interesting for a number of reasons, not the least of which is that the crank is not made in China.

I have a special place for the proclamation that the world does not need a $1,000 titanium crank. First, this begs the question of what any of us really needs to enjoy riding a bicycle much less just to survive. If you’re reading this, odds are you’re a bit past the fight for survival stage. Not to get philosophical, but we live in a WANT society and hopefully in relation to cycling the WANT is something that enhances our riding experience. Second, so a $450 carbon crank is attainable for some and subjectively deemed worthwhile – by those that have or can attain one! So maybe the rider with the $80 SLX aluminum crank thinks no one NEEDS at $450 carbon crank! Lastly, there are many, many things in life that I neither need nor can afford. However, some of those things I appreciate for their beauty, for the fact that someone achieved their dream, because they accomplished something others could not, or for the honorable reason of simply making the best possible thing. I’ll sign off with “to each his own.”

Monday: 10:00 am – 5:00 pm

Tuesday – Thursday: 10:00 am – 5:00 pm

Friday: 10:00 am – 5:00 pm

Saturday – Sunday: Closed